Speed up your work, our robots handle the risks

Custom robots to transform your hazardous, strenuous, and repetitive tasks.

For 20 years, Roboplanet has been supporting organizations seeking to transform their complex, costly, and high-risk operations.

Roboplanet is a unique company: it is involved at every stage of a successful robotic transition — from design to operational implementation alongside your teams, and through to maintaining operational readiness.

Originally specialized in the automation of Non-Destructive Testing (NDT) on ship hulls,

the company then focused on eliminating high-access operations for thickness inspections of storage tanks (PM2I, EEMUA 159, API653), spheres, furnaces, cyclones, and pipe racks.

It later expanded into mitigating risks related to confined space interventions (floating-roof tanks, penstocks), underwater operations (cleaning and inspecting ships afloat), and radiologically active areas.

Our areas of expertise include:

Supporting the robotic transformation of strenuous and hazardous tasks in close collaboration with industrial partners

Designing robots and remotely operated systems

Operational deployment, including on high-risk sites

Marketing, training, and maintenance of robotic equipment

Our fields of expertise :

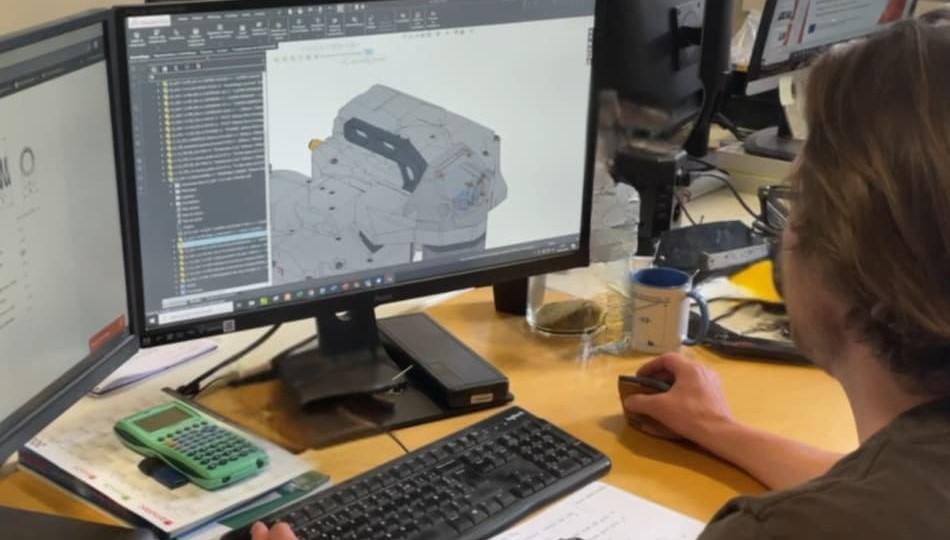

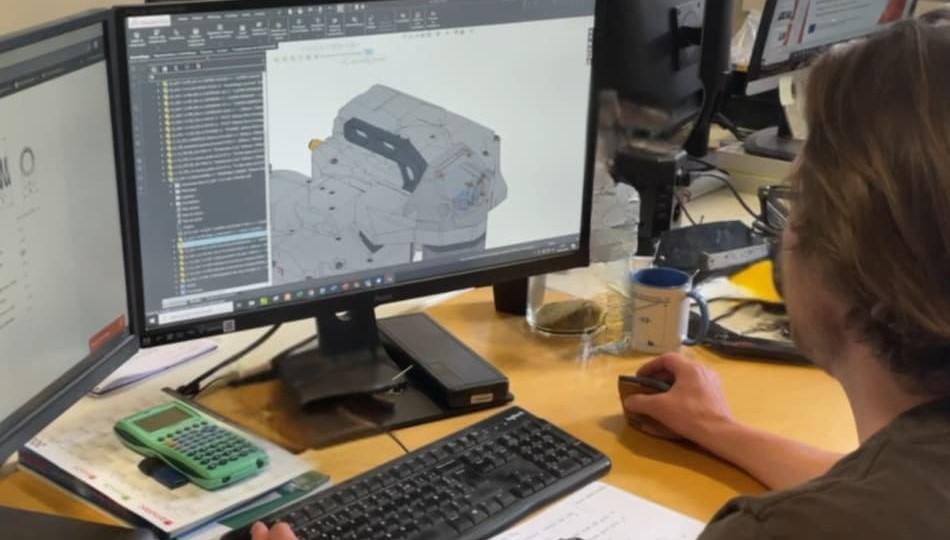

Drafting specifications, conducting feasibility studies or building prototypes, industrializing production, and planning the full lifecycle:

Our project managers and engineers support you with innovative projects and special developments.

Drafting specifications, conducting feasibility studies or building prototypes, industrializing production, and planning the full lifecycle:

Our project managers and engineers support you with innovative projects and special developments.

A specific operation? Need inspection and testing of storage tanks subject to DT94 / PM2I regulations?

Deploy a team of specialists and roboticists for a turnkey robotic service.

A specific operation? Need inspection and testing of storage tanks subject to DT94 / PM2I regulations?

Deploy a team of specialists and roboticists for a turnkey robotic service.

Get a robot to gain agility and autonomy in your inspections.

Discover robust, industrial-grade solutions. These systems are available for short-term troubleshooting and testing, or for long-term use.

Get a robot to gain agility and autonomy in your inspections.

Discover robust, industrial-grade solutions. These systems are available for short-term troubleshooting and testing, or for long-term use.

Industry leaders trust us

Our Products

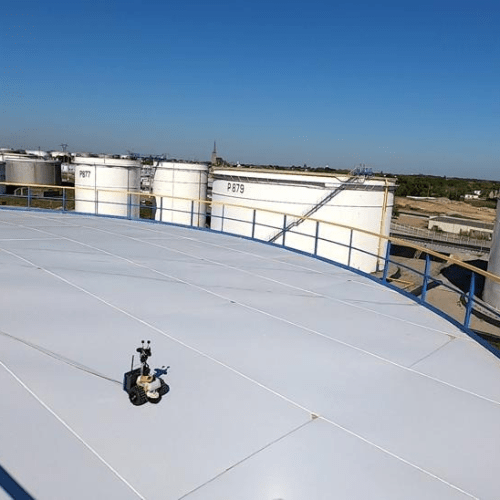

For fast and safe inspections of storage tanks.

The safest and most advanced ultrasonic crawler available. As the flagship of our product line, Altiscan is continuously designed and optimized.

Its unique capabilities including mobility on foam covered surfaces and in heavy rain make it the safest solution on the market.

Its unmatched speed makes it a cost effective alternative, even when compared to riskier methods such as rope access work.

For fast and safe inspections of storage tanks.

The safest and most advanced ultrasonic crawler available. As the flagship of our product line, Altiscan is continuously designed and optimized.

Its unique capabilities including mobility on foam covered surfaces and in heavy rain make it the safest solution on the market.

Its unmatched speed makes it a cost effective alternative, even when compared to riskier methods such as rope access work.

The instrumented pole for low-clearance areas

The UT_Pole is designed to simplify ultrasonic thickness measurements and visual inspections on complex metal surfaces.

With its telescopic extension reaching up to 12 meters, it enables both internal and external inspections without the need for high-access equipment, ensuring operator safety.

Robust and easy to use, the UT_Pole navigates challenging geometries and secures inspections of tank roofs or insulated structures.

Manufactured in France, it features advanced software for data collection and analysis, making it a reliable and high-performance tool for industrial service providers.

The instrumented pole for low-clearance areas

The UT_Pole is designed to simplify ultrasonic thickness measurements and visual inspections on complex metal surfaces.

With its telescopic extension reaching up to 12 meters, it enables both internal and external inspections without the need for high-access equipment, ensuring operator safety.

Robust and easy to use, the UT_Pole navigates challenging geometries and secures inspections of tank roofs or insulated structures.

Manufactured in France, it features advanced software for data collection and analysis, making it a reliable and high-performance tool for industrial service providers.

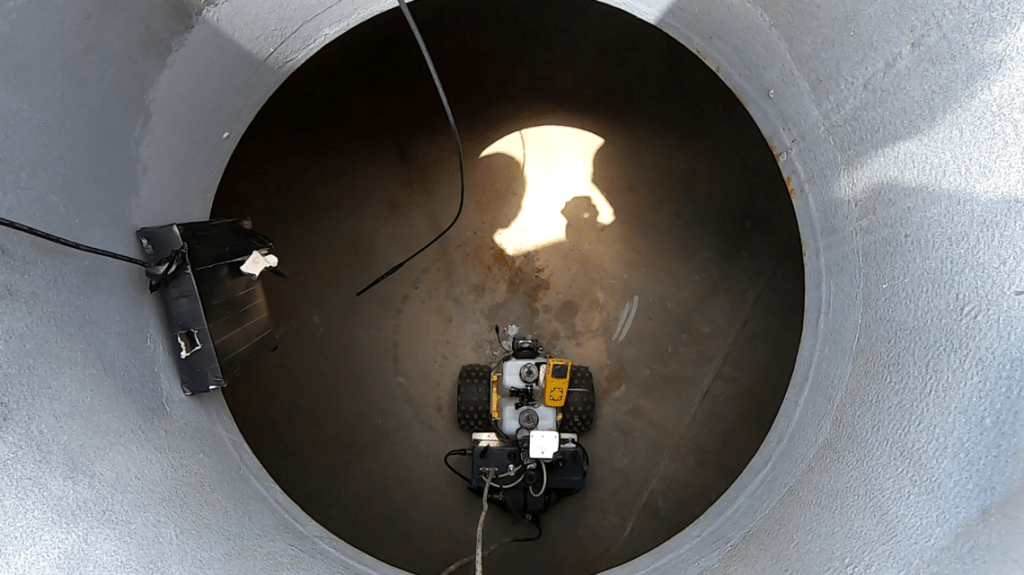

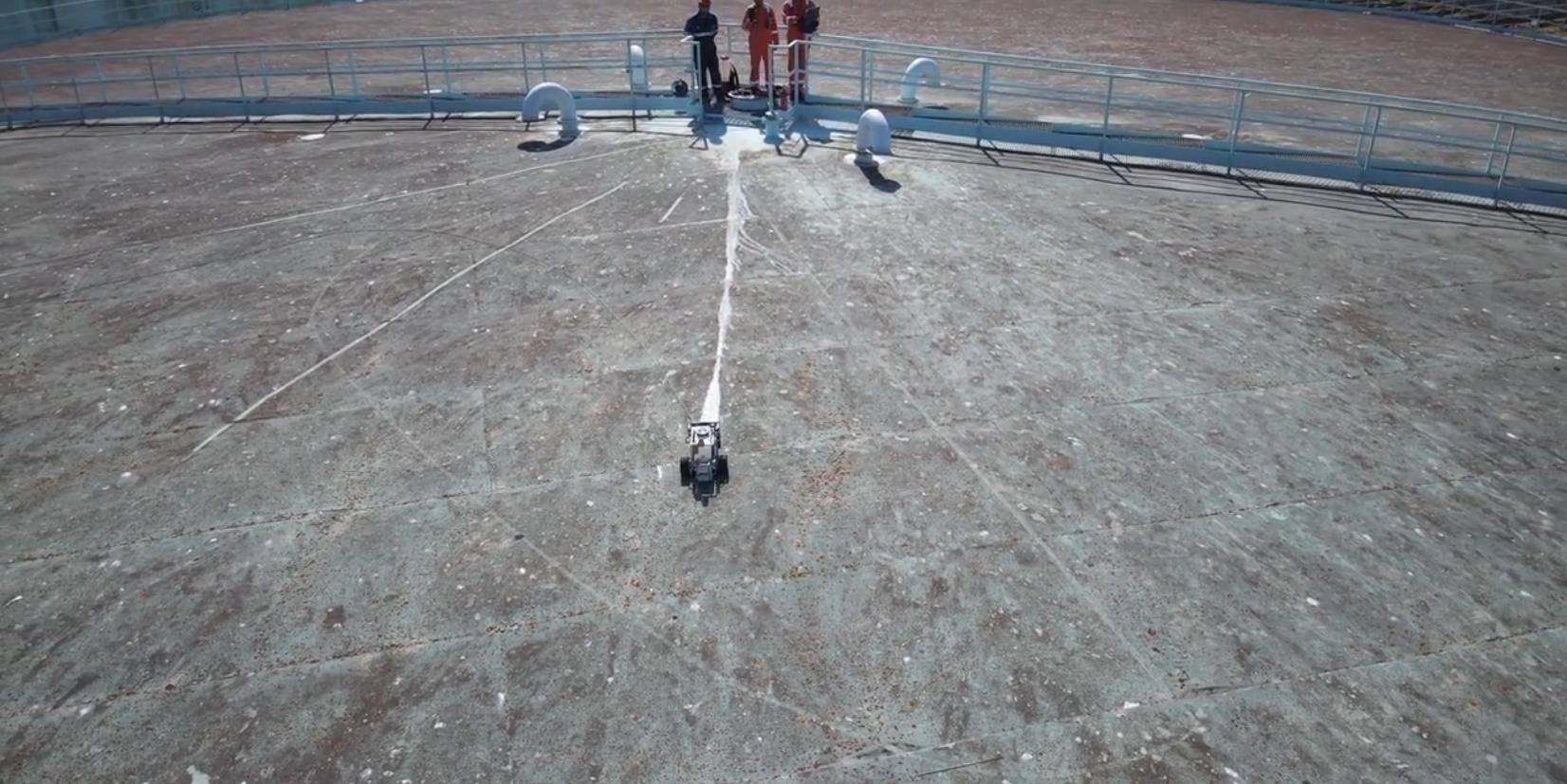

For safe inspection of uncertain fixed and floating roofs

The UT_Rover is designed to perform safe and accurate inspections in uncertain or high-risk areas.

With remote control operation, it eliminates operator exposure while ensuring optimal reliability.

Specifically tailored for uncertain fixed or floating-roof tanks, the UT_Rover offers a range of up to 100 meters for ultrasonic measurements and up to 1 kilometer for visual inspections.

Thanks to its customizable modules, it meets the specific needs of industrial clients and inspection service providers.

Manufactured in France, the UT_Rover sets new HSE standards for inspections in demanding environments.

Gallery

Automating dangerous operations means gaining agility, easier preparation, and better-quality results.

Entrust us with the development of your innovative access solutions.

An experienced engineering office to support your projects. Whether as a direct partner or within a consortium, we accelerate your robotic transition.

From requirements specification to operational implementation, we’re by your side every step of the way.

Rely on our experience with dozens of successfully deployed projects.

Across all sectors of industry and defense.

For high-access operations, confined spaces, underwater work, radiologically active areas, and combat zones.

"For 20 years, Roboplanet has been accelerating processes and keeping your teams safe."

Enhance safety :

Eliminate risks to reassure your teams.

Reduce downtime :

In-service interventions improve the availability of your assets.

Reduce costs :

Fewer access systems, less administrative burden — up to 90% reduction.