Storage Tank Shell Inspection: Thickness Measurement Without Working at Heights

Some storage tanks are exposed to degradation that can weaken them and lead to accidents.

They must be regularly monitored to prevent these risks. Tanks that store products hazardous to people or the environment are subject to regulatory inspections, as outlined in the decrees of October 4th and 5th, 2010. This Industrial Facilities Modernization Plan (PM2I) covers inventory, initial condition assessment, and the required inspection plan.

Client challenges

The most common degradation mode is internal wall thickness loss. This typically occurs in the vapor space and is accelerated by factors such as the acidity, temperature, or density of the stored product.

To quantify these losses, wall thickness measurements are taken. These are considered work-at-height operations, which involve specific risks and therefore require the use of access equipment such as scaffolding, aerial work platforms, or rope access technicians.

These access methods themselves involve work at height (e.g., scaffold assembly, platform setup) and may raise legal concerns—such as the use of rope access workers when less hazardous alternatives exist (Article R4323-64 of the French Labor Code). In terms of cost, erecting scaffolding is almost always more expensive than the inspection itself…

SOLUTION

For these reasons, a maintenance manager at a sugar plant consulted us. He wanted to inspect the shell of an 8-meter-high storage tank without using access equipment.

We have been developing robots and solutions for over 10 years that help operators avoid taking unnecessary risks in their work environment. For this industrial client, we deployed the UT_Pole system. This is a wheeled carrier equipped with magnets, allowing it to inspect steel walls. It carries a thickness measurement chain that records wall thickness every centimeter, storing the digitized signal for later analysis.

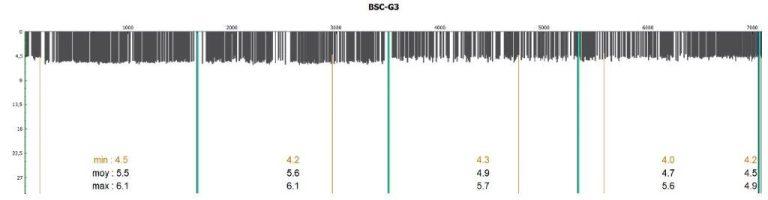

The carrier is deployed up to 12 meters in height using a telescopic pole. This enables the operator to reliably detect uniform corrosion, and to a lesser extent, localized corrosion. Additionally, the B-scan report provided gives the client a clear profile of the shell thickness of the tank. Thousands of data points are summarized and ready to be used for engineering calculations and planning future maintenance operations.

On this project, the special design of the UT_Pole allowed for a fast and low-footprint intervention.

RESULTS

n conclusion, it took us just 2 hours on site to complete the inspection of the tank’s 4 vertical weld seams. As a result, our client saved several hours of work, simplified the intervention’s management, and benefited from a much more detailed report thanks to the B-scan.