We create value for our clients

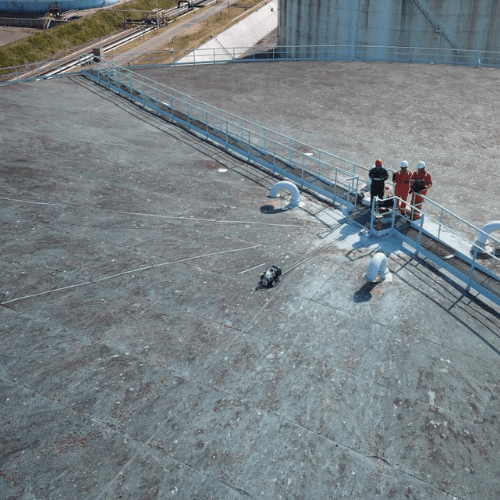

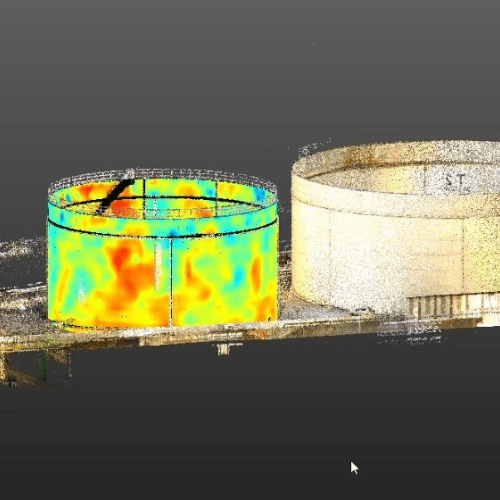

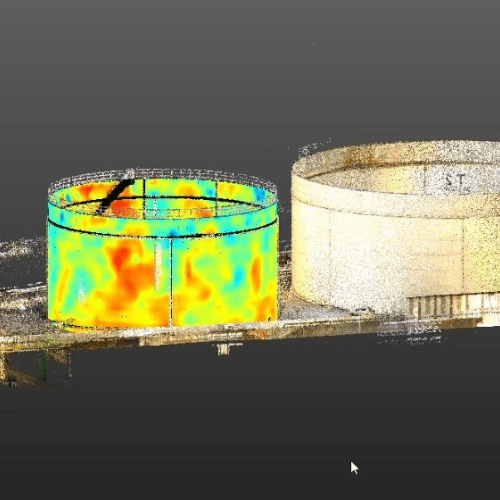

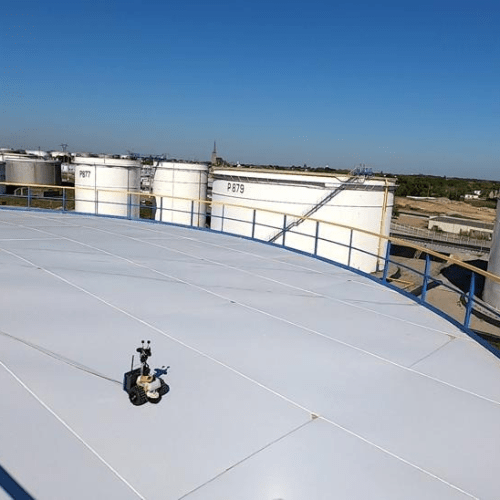

Our robots, such as the ALTISCAN, can inspect up to three tanks per day with exceptional precision, reducing intervention times by a factor of four compared to traditional methods. Each 10-meter generator is scanned efficiently even in challenging conditions like rain, wind, or complex surfaces. Our solutions comply with the most demanding industrial standards, including API 653, CODRES, and EEMUA, ensuring inspections meet regulatory audit requirements.

As a family-run business, we value a human, personalized approach. We support our clients at every stage of their project from the design phase and technology selection to the exploitation of collected data. Our robots, tested and validated in real-world conditions, eliminate risks to your teams while improving inspection reliability.

With over 1,500 tanks inspected to date, we have worked with major players such as TOTALENERGIES and the INSTITUT DE SOUDURE, continuously enhancing our services through field experience. Thanks to our solutions, you can reduce operational costs, optimize turnaround times, and ensure your teams’ safety all while benefiting from innovation tailored to your needs.

A guarantee of quality and safety

Mase

The MASE certification reflects our commitment to safety, health, and the environment. It guarantees our clients services that meet the highest standards, with strict on-site risk management.

Cofrend

The COFREND certification attests to our expertise in non-destructive testing (NDT) and ensures that our inspections comply with the strictest standards. It reflects our commitment to quality and the reliability of the services we deliver to our industrial clients.

Safety and precision in the field

Working at height:

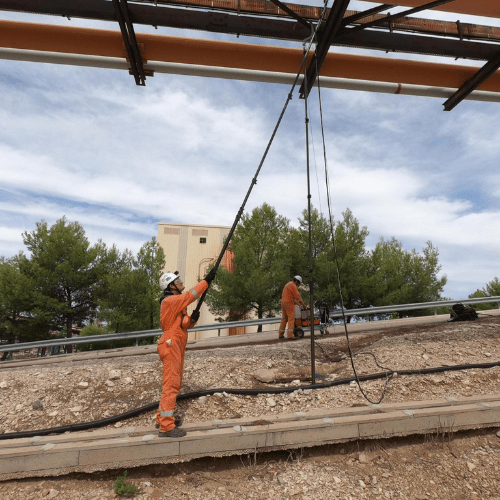

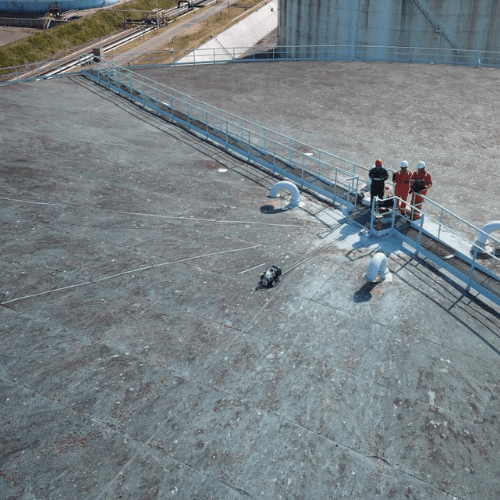

Our robots eliminate the risks associated with working at height by performing inspections from the ground or remotely, ensuring operator safety.

Operations in “No Man Entry” zones:

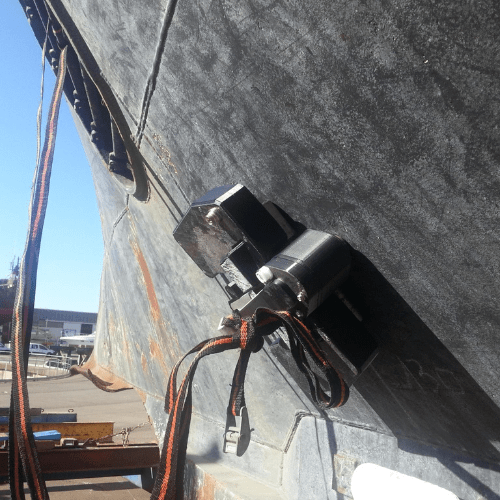

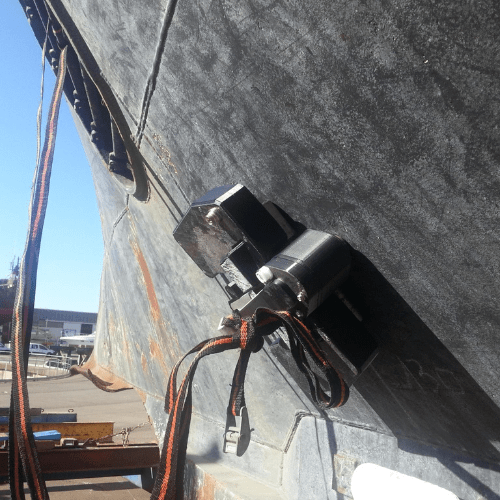

Interventions in hazardous or confined environments are carried out without direct human exposure, thanks to our magnetic and remote-controlled robots.

Guaranteed Safety:

Zero accidents recorded over thousands of working hours, thanks to solutions that minimize exposure to hazards.

Inspection Performance:

Ability to inspect up to 3 tanks per day or 10-meter generators, even in challenging conditions (wind, rain, greasy surfaces).

Cost Reduction:

Elimination of expensive access methods (scaffolding, aerial platforms) and risks linked to simultaneous operations, optimizing inspection budgets.

Standards Compliance:

Conformity with industrial standards such as API 653, CODRES, and EEMUA, ensuring services meet regulatory requirements.

Field-Proven Experience:

Over 1,500 tanks inspected to date, with established partnerships with industry leaders like TOTALENERGIES and the INSTITUT DE SOUDURE.

Roboplanet is:

Our expertise in pictures

Facing a challenge? Let’s find the solution together!

Frequently Asked Question (FAQ)

Why should I pay for an on-site service if I can train my teams internally?

Our on-site services give you immediate access to efficient, proven solutions—without the burdens of management, training, or associated risks. We deliver concrete, measurable results while providing you with peace of mind.

How much will I actually save with this service?

Our services reduce intervention times by up to four times compared to traditional methods, significantly minimizing production downtime. You also save on costs related to safety, access equipment (such as scaffolding and lifts), and internal team training. These combined savings help optimize both your budget and operations.

What standards do your interventions comply with? Are they sufficient to pass a regulatory audit?

Our services comply with the most demanding industrial standards, including API 653, CODRES, and EEMUA. Our robots and inspection reports are designed to meet current regulatory requirements, ensuring successful audits and full compliance with legal obligations.

Do your tools work in real-world conditions or only in standardized environments?

Our robots, such as the ALTISCAN and UT_Rover, are tested and validated in real-world conditions, including challenging environments like rain, strong winds, and complex surfaces. They have already been successfully deployed on over 1,500 tanks and various critical infrastructures.

What is the accuracy of the inspections carried out by your robots? How do your results compare to a manual inspection?

Our robots, such as the ALTISCAN, offer high precision with ultrasonic measurements reaching up to 100 points per second. Unlike manual inspections, our robots rapidly cover large surfaces while eliminating human error, ensuring more reliable and consistent results.

Proposez-vous un suivi après votre intervention ?

Oui, nous offrons un suivi complet après chaque intervention, incluant des rapports détaillés, une assistance pour interpréter les données collectées et des recommandations pour vos prochaines étapes. Nous restons disponibles pour répondre à vos besoins spécifiques ou pour des inspections complémentaires

Contact us for your inspection challenges!

Feel free to request a quote — our team is here to support you with your projects. Whether you need a solution tailored to your needs or personalized advice, we’re here to guide you every step of the way